- ● Product List

- Tungsten Carbide Drawing Dies

- Tungsten Carbide Wire Drawing Dies

- Tungsten Carbide Bar Drawing Dies

- Tungsten Carbide Tube Drawing Dies

- Tungsten Carbide Tube Drawing Dies Plug

- -S30 Carbide Drawing Die for Plugs

- -S30-A Carbide Drawing Die for Plugs

- -S30-AB Carbide Drawing Die for Plugs

- -S31 Carbide Drawing Die for Plugs

- Carbide Rolls

- Carbide Roll Rings

- Grooved Roller

- Roll Rings for High Speed Rolling of Ribbed Steel Bars

- Wire Guide Die

- Powder Coating Die

- Peeling Dies

- Custom Drawing Dies

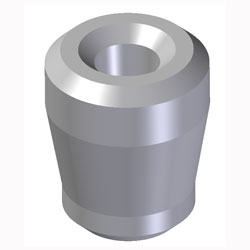

Tungsten Carbide Tube Drawing Dies Plug

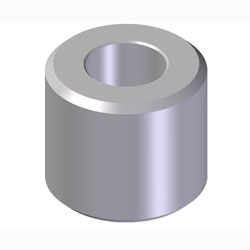

- S30 Carbide Drawing Die for Plugs

- S30 cemented carbide drawing die for mandrel is widely used in reducing size of metal mandrels. It is utilized in metalworking process. Tungsten carbide drawing dies for plugs are mainly made from rare microcrystal carbides and cobalt powder ...

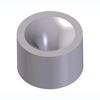

- S30-A Carbide Drawing Die for Plugs

- S30-A tungsten carbide drawing dies for mandrels are commonly used in metalworking process. With carbide drawing die for plugs, metal plugs or mandrels are reduced into smaller ones. Drawn metal mandrels can be made from various metal materials...

- S30-AB Carbide Drawing Die for Plugs

- S30-AB carbide tube drawing dies for mandrels can reduce cross sections of various mandrels which are made from ferrous metals and non-ferrous metals. Generally, carbide tube die for plugs is performed at room temperature, but if mandrels are large...

- S31 Carbide Drawing Die for Plugs

- S31 tungsten carbide dies for mandrels are important tools in metalworking. They can reduce cross sections of metal mandrels by drawing these mandrels through drawing holes. Cemented carbide drawing dies for plugs are often working ...

Tungsten carbide tube drawing dies for mandrels are used to reduce cross sections of metal mandrels by stretching these mandrels through die holes. Generally, drawing is performed at room temperature. But if mandrels are in large size, carbide drawing dies for plugs will work at elevated temperature. In manufacturing process of drawing dies, advanced low-pressure sintering technology is applied. Hence, our drawing die products maintain advantageous features of tungsten. At the same time, other advantageous performances are increases by 1/4.

CompositionsTungsten carbide tube drawing dies for mandrels are made from rare microcrystal carbides and special metal powders. These microcrystal carbides are featured by strong hardness and high melting points. As to metal powders, we apply high-purity cobalt powder as binders. Cobalt powder endows drawing dies with strong toughness.

ApplicationCarbide drawing dies for plugs are widely used to draw various ferrous metals and non-ferrous metals, including steel, stainless steel, copper, aluminum, metal alloy, etc. As necessary tools in steel industry, tungsten carbide tube drawing dies for mandrels affect quality of tube products immediately. Drawn metal plugs are commonly used in molding industry.

Products1. S30 Carbide Drawing Die for Plugs

2. S30-A Carbide Drawing Die for Plugs

3. S30-AB Carbide Drawing Die for Plugs

4. S31 Carbide Drawing Die for Plugs

1. Tungsten carbide tube drawing dies for mandrels are convenient to fit into draw benches.

2. Carbide drawing dies for plugs are featured by long working life and high cost performance ratio.

3. With good wear resistance, they can work continuously for a long time. Apart from this, drawing is accurate.

4. They are finely polished during manufacturing process. Besides, small adhesion arises between die surface and mandrel surface. Both features above can make mandrel surface glossy and in high quality.

5. Small friction coefficient can economize electric energy and increase working efficiency.

6. Tungsten carbide tube drawing dies for mandrels are featured by high thermal conductivity. In heat drawing, heat is released fast.

7. Good corrosion resistance presents advantages when performing wet drawing in lubricants, especially in acidic lubrication oils.Notes before Purchase

1. Before choosing suitable carbide drawing dies for plugs, please tell us what types you prefer.

2. Metal materials of mandrels should also be taken into considerations when choosing right products.

3. If you have specific requirements for drawing die parameters, let us know. We can do our best to improve tungsten carbide tube drawing dies for mandrels.

There are several important structures in drawing dies: entrance area, lubrication area, working area, sizing area, exit area and exit cone angle.

1. Entrance area plays a transition role in facilitating drawing materials into working area so that metal materials would not be scratched by the edge of die hole.

2. Lubrication area is to store lubricant so that drawing process is completed successfully.

3. Working area of tungsten carbide tube drawing dies for mandrels is where metal materials begin to be stretched into new mandrels. Principles to select working area length are as follows:

(1) Working area used for stretching soft metals is shorter than that for hard metals.

(2) Working area used for small-diameter mandrels is shorter than that for large-diameter mandrels.

(3) Working area used under wet lubrication is shorter than that under dry lubrication.

4. Sizing area of carbide drawing dies for plugs decides the final dimension of metal materials. Length of sizing area varies with different hardness. If sizing area is too long, friction will increase, which has negative impact on working life of drawing dies. But if sizing area is too short, change of cone angle will influence the size of metal materials.

5. In tungsten carbide tube drawing dies for mandrels, exit area is the last part passed by metal materials. It is designed to protect sizing area from cracking. Exit cone angle is to protect completed metal rods.

Founded in 1993 and with fixed assets over 38 million RMB, TallKee Cemented Carbide is a specialist manufacturer dedicated in production of superior cemented carbide dies. Our tungsten carbide dies are commonly used in iron industry and steel industry. They are inspected under strict quality tests and have passed ISO9001:2000. Besides, our tungsten carbide tube drawing dies for mandrels are widely sold at home and abroad. They are mainly exported to North American countries, Japan, Korea, India, Taiwan, Southeast Asia, etc.

- Tungsten Carbide Tube Drawing Dies

- Tungsten carbide tube drawing dies are designed with round, square, hexagon and other special shapes. They are used for drawing various ...

- Tungsten Carbide Bar Drawing Dies

- Bar drawing dies in manufacturing industry are usually made of carbides or tool steel. Rod or bar drawing is a term used to express one of ...